Maximizing Warehouse Capacity

페이지 정보

본문

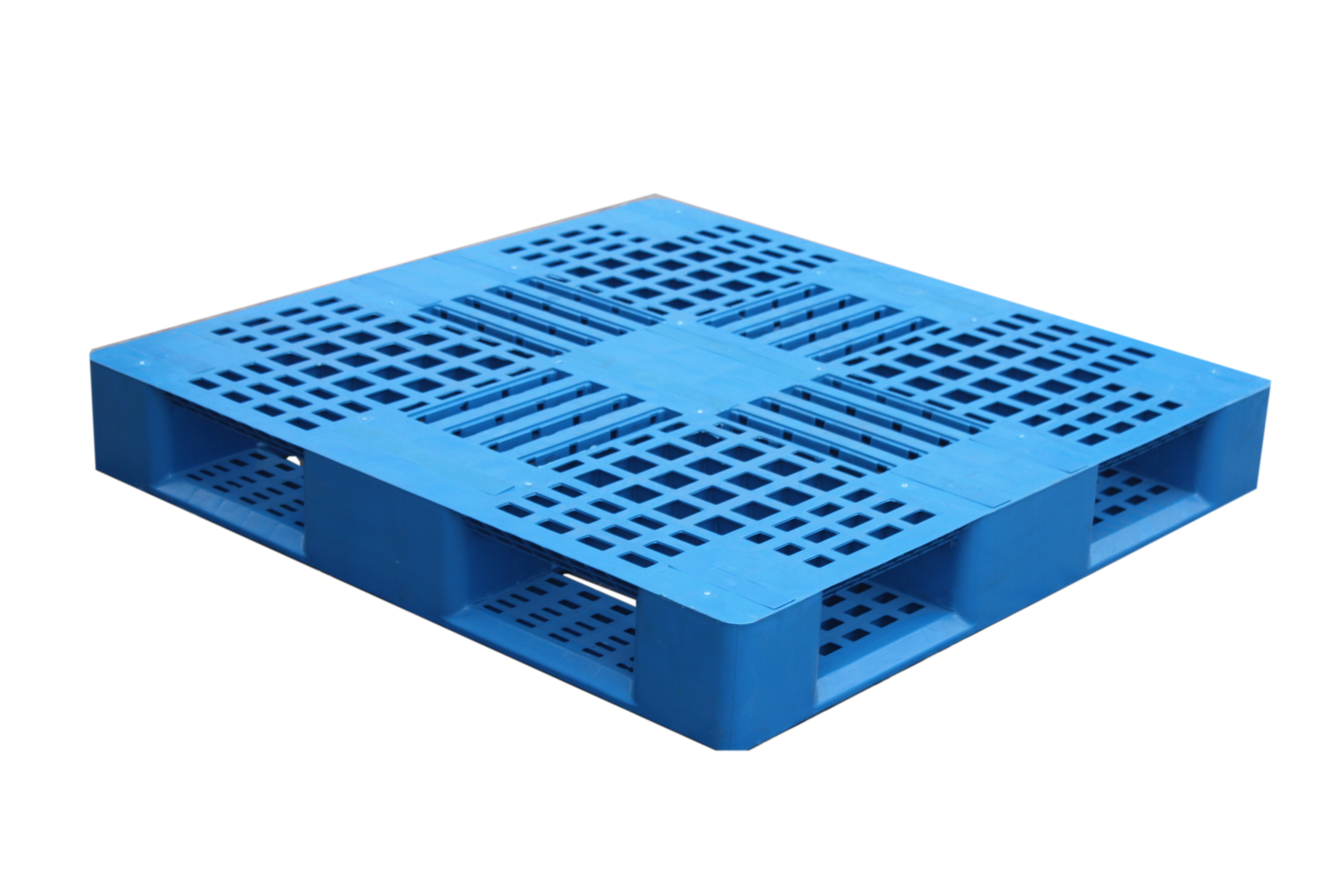

Optimizing warehouse capacity is a constant concern for businesses, as it directly impacts their bottom line. One effective solution to optimize space is by implementing vertical storage systems, these systems allow for the removal of obstructions and hindrances in traditional horizontal shelving systems, in turn providing more usable square footage for inventory storage.

Optimizing warehouse capacity is a constant concern for businesses, as it directly impacts their bottom line. One effective solution to optimize space is by implementing vertical storage systems, these systems allow for the removal of obstructions and hindrances in traditional horizontal shelving systems, in turn providing more usable square footage for inventory storage.Multi-level racking systems can be configured in various layouts such as flow racking. These settings cater to different types of inventory storage, considering factors such as storage requirements.

1. Reduced Floor Space: One of the most significant benefits of multi-level racking systems is the considerable reduction in floor space required for inventory storage. By going vertical, businesses can maximally utilize the ground and make room for other core operations such as inventory handling.

2. Inventory Tracking: Effective inventory control plays a critical role in maintaining accurate inventory levels, avoiding stockouts, and ensuring that sensitive items get timely distribution. Multi-level racking facilitates precise inventory tracking as items are stored in neatly organized racks, プラスチックパレット allowing for easy identification and removal of misplaced merchandise.

3. Space-Efficiency: These flexible storage systems optimize the storage space by condensing stored products in multi-stories, also enabling businesses to store both heavy and valuable items in different sectors that are often protected from environmental factors and damage.

4. Minimized Warehouse Disruptions: Multi-level racking systems don't require extra support columns due to load balancing across different storage levels, making them ideal for warehouse spaces with limited perimeter space. It minimizes the chances of warehouse disruptions caused by unpleasant metal columns.

However, multi-level racking systems do have their own boundaries. Before deciding to go for one, consider:

1. Budget Constraints: In addition to capital expenses associated with getting and configuring, you will also have the ongoing costs, such as energy consumption to operate conveyancing equipment and {install<|u> costly support systems in your {building|structure}.

2. Limited Zone Design and Maintenance: Some facilities might not {easily|practically} switch to multi-level racking systems, this is because many business owners will {consider|give weight} to {design and re-organization costs|redesigning and reorganizing expenses} that {help|assist} or {prevent|deter} upgrading the inside {area|space} of your building where such system can be taken over.

3. Operations and Safety Safety Regulations: Given the fact that the {heavier|bulkier} inventory {hangs|matures} is needed to be piled at {high|upper} levels or higher storages, some business can take some extra {investment|capital} to organize its {operations|functions} for moving the materials from storage with the {precise|accurate} {regulations|standards} put forward by the {building|government} bodies and national {regulations|guidelines}.

- 이전글Play & Earn Real Money on Nagaland State Lottery Results Today 8PM 2025 – TC Lottery 25.04.14

- 다음글По какой причине зеркала официального сайта онлайн казино Ramenbet сайт так необходимы для всех клиентов? 25.04.14

댓글목록

등록된 댓글이 없습니다.